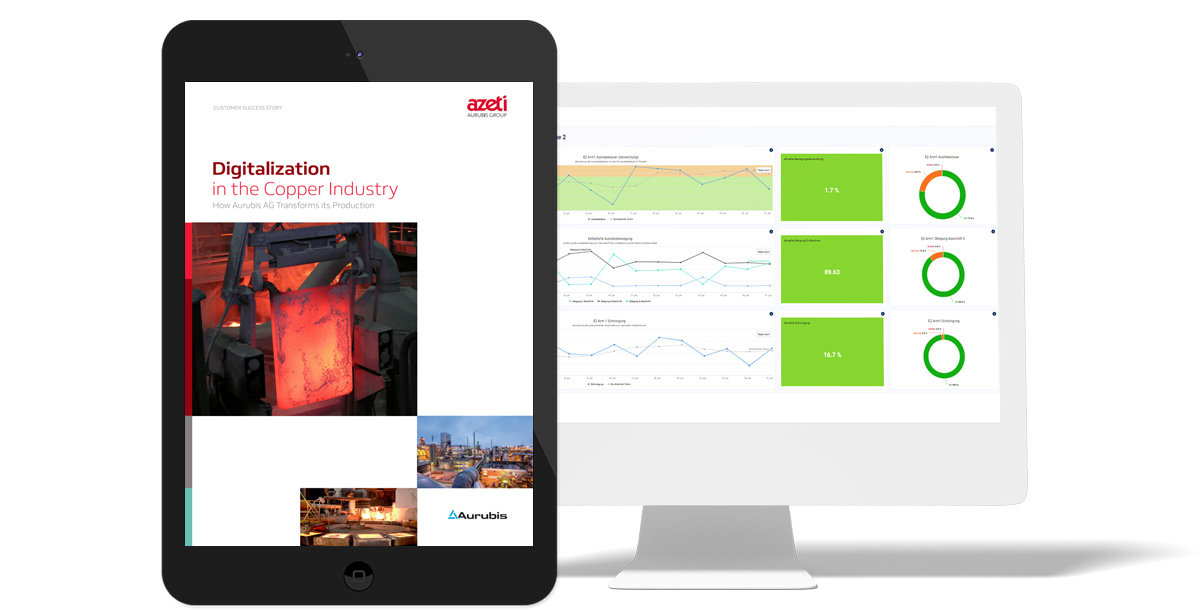

Platform

APPLICATIONS

Learn how the industry benefits from the Industrial Internet of Things with application examples.

Sonarplex

Applications

Learn how the industry benefits from the Industrial Internet of Things with application examples.

Company

Team

Learn more about our international team and what drives us every day

Career

Become a part of the azeti family: Our current vacancies at a glance

About Us

We were shaping the future before "IoT" was even an issue

Research

Valuable results from research projects in the past enabled the development and implementation of numerous potentials

Platform

APPLICATIONS

Learn how the industry benefits from the Industrial Internet of Things with application examples.

Sonarplex

APPLICATIONS

Learn how the industry benefits from the Industrial Internet of Things with application examples.

Company

Team

Learn more about our international team and what drives us every day

Career

Become a part of the azeti family: Our current vacancies at a glance

About Us

We were shaping the future before "IoT" was even an issue

Research

Valuable results from research projects in the past enabled the development and implementation of numerous potentials