There is no IoT without Data

We are surrounded by IoT applications in many areas of our professional as well as private lives. In the industrial field, the underlying technology enables us to keep track of the condition of machines, allowing us to know in advance when service is required or something along the production process is (about to go) wrong. We can compare utilization and overall equipment effectiveness across production facilities and can automate spare part ordering processes.

IoT is evolving from niche to mainstream. Benefits are not anymore doubted or argued. The value of it is generally acknowledged and even critics accepting that IoT has its place in the industrial sector.

But all of IoT is nothing without data - or to be specific the supply of data generated by "Things". No matter if we look at nice graphs or deploy massive machine learning algorithms. It only becomes relevant if there is data to feed data science applications or populate dashboards with useful information.

So where do we get the data from? To answer that question, we have to take a closer look at:

- Things generating data

- Accessing the data

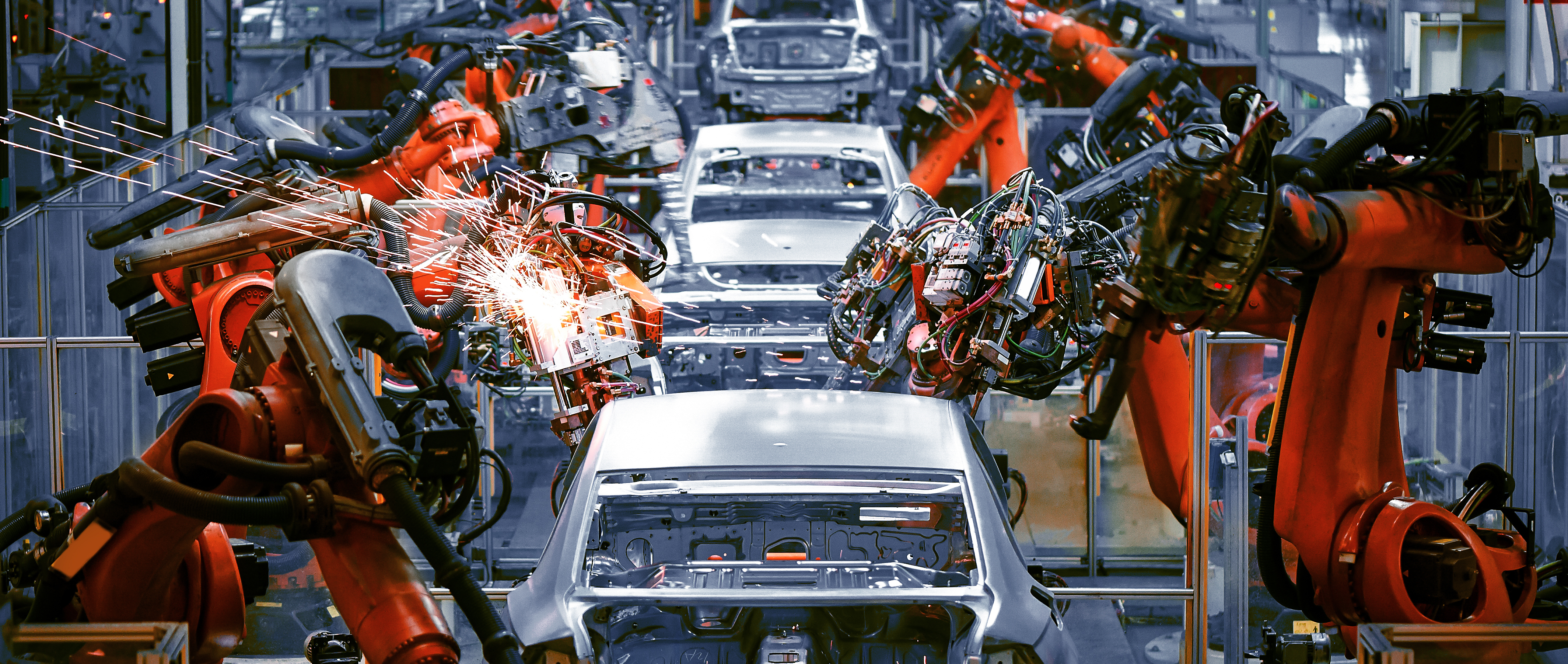

To discuss this in more detail, we use a production line as an example. There are different machines involved at different stages of the production. Every machine generates vast amounts of data that can describe:

- their own condition (machine health),

- their performance in the production process, and

- their impact on the workpiece / product during the manufacturing process

All of the above is valuable information that provide a foundation to assess the performance and effectiveness of machines and the production process or to identify early if a machine is likely to fail or requires maintenance.

With systems in place that allow collection and evaluation of data from PLCs or sensors that are connected to the machines, people can take and implement decisions backed by data that help to optimize the overall production process even more or to allow them to take action in order to prevent downtime.

Those systems would provide a digital representation of the production process and each machine involved. But accessing the data is the tricky part.

Where to find the data to feed the IoT?

A production line is usually a heterogenous environment. That means you don't have a single type or vendor of a machine with the same interface, but rather looking at various machines of different type and age, featuring a variety of interfaces to connect to. Some of the data may be collected by connecting to PLCs. But even here heterogeneity strikes again as there is a good chance that different models of machine control systems might be used. A production line can have PLCs from Siemens, Rockwell, ABB, Mitsubishi and so on, and they may all use a different protocol to communicate.

That said, PLCs may or may not hold all information you need to have the aforementioned digital representation of the production process. But if you are interested for instance in the health of a specific machine, you may need to retrofit it with additional sensors (e.g. vibration and temperature or power sensors) to get all the data you need for your machine health application. So this adds even more complexity to the setup.

To sum it up, the extraction/collection and aggregation of data in order to build a digital representation of a production process to address use cases around condition monitoring and predictive maintenance, is a challenging thing.

How to overcome challenges due to heterogeneity in manufacturing?

Therefore, azeti built an Application Enablement Platform (AEP) that is made to deal with those heterogenous environments that are common in manufacturing. With the azeti platform, it doesn't matter if you have different PLCs or need to retrofit a machine with sensors, since it is capable to connect through a variety of protocol adapters (incl. Profibus, Profinet, Modbus RTU/TCP, Ethernet IP, OPC-UA and many more). A PLC wizard allows to automate most of the work for onboarding new machine control systems onto the platform making it very easy to use the azeti platform also for everyone.

Once a connection is established between the platfrom and the machine’s PLC or sensors, azeti's software starts to collect and aggregate all the data from the entire production line and converts it into a standard format (JSON). From there users of the platform can either use azeti's built in Dashboards to visualize the data or simply use our APIs (REST, GraphQL, direct MQTT stream) to feed their systems and applications (e.g. for predictive maintenance) with data from the entire production line.

azeti provides a new abstraction layer where data from all machines and sensors independent of type, age or interface is combined and made accessible as live data and historic data. Hence, azeti's platform is used as a foundation for many IoT applications that are out in the field supporting operations in manufacturing and other industrial verticals.